Universal Robots e-Series

Universal Robots e-Series

The “e” in Universal Robots new e-Series line stands for empowering, ease of use, everyone, and evolution. Universal Robots e-Series is positioned as the premium collaborative robot product line, which delivers the unique combination of broad application coverage and simple deployment. The features that separate the e-Series line from the original Universal Robots line are:

Elbow safety (force, speed, boundary restriction)

Elbow safety (force, speed, boundary restriction)- Built-in force torque sensor

- New safety features: 17 safety functions, including customizable stopping time and stopping distance. The stopping time limit limits the maximum time the robot uses for stopping after a protective stop is initiated. The stopping distance limit limits the maximum distance travelled by the robot after a protective stop is initiated

- Lighter and more responsive teach pendant

- Expanded application reach

- Enhanced user experience

- Improved teaching and configuration

- New cleanroom class 5

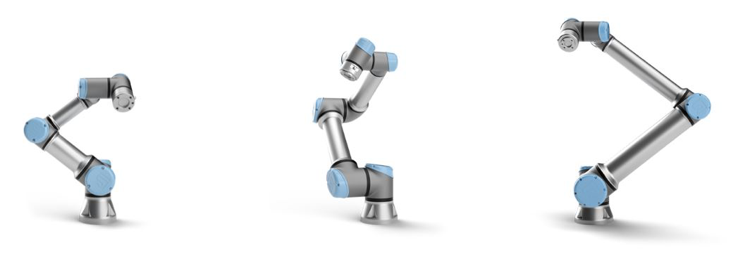

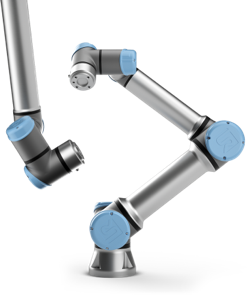

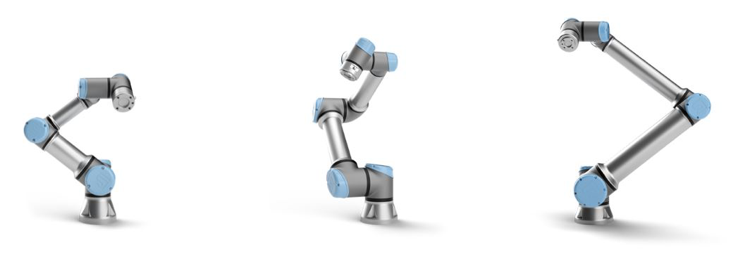

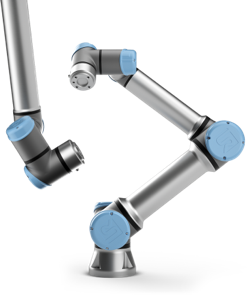

- New design with an updated feel and look

- Improved programming flow

- Payload and CoG estimation wizard

- New waypoint concept

- Feature plane teach-in wizard

- More easily replaceable joints

All of the Universal Robots models can boast:

- Lightweight, space-saving, easy to re-deploy to multiple applications without changing production layouts

- One hour is all it takes to unpack the robot, mount it, and program the first task

- 87 minutes to turn anyone into a robot programmer with Universal Robots Academy

- They do not require special electrical installations, and can be connected to any regular power outlet

- Diverse application coverage: Precision palletizing, quality assurance inspection, injection molding, industrial pick & place, industrial assembly

Business benefits of using Universal Robots:

Achieve faster assembly, greater output and better quality

Achieve faster assembly, greater output and better quality- Make assembly operations close to heavy machinery safer

- Use with virtually any materials

- Re-deploy easily as prompt response to changing requirements

- Free up employees for higher-value work

- Reduce waste and increase accuracy by using a cobot for tasks such as gluing, dispensing and welding

- Reduce cycle time and improved product quality

- Easy-to-understand programming by simply moving the cobot into the required positions

- Small and lightweight, easy to install and use even in restricted spaces

- Improved working conditions because operators no longer have to carry out tasks that are repetitive or dangerous

Universal Robots e-Series

Universal Robots e-Series Elbow safety (force, speed, boundary restriction)

Elbow safety (force, speed, boundary restriction) Achieve faster assembly, greater output and better quality

Achieve faster assembly, greater output and better quality