Pharmaceutical & Medical Industry Solutions

Cognex: a Leader in the Pharmaceutical & Medical Industry

Meet all Your Tough Manufacturing Goals with Machine Vision & ID

The need to comply with patient safety and traceability requirements in a cost-effective way is a major business driver for pharmaceutical and medical device product manufacturers. These manufacturers know that quality inspection is critical to success. Liability for defective product, inconsistent quality, rapidly changing costs, increased global competition and pending Unique Device Identification (UDI) regulations all challenge profitability. To achieve the quality that customers demand and comply with regulations, pharmaceutical and medical device manufacturers increasingly rely on the topnotch machine vision and ID solutions that we supply.

- Achieve Tracking & Traceability

- Check for Debris

- Maintain Consistent Product Appearance

- Detect Package Imperfections

- Confirm Product Matches Label

- Locate Inkjet Code Strings

- Prevent Counterfeiting

- Protect the Brand

- Match Package to Product

- Read Codes and Verify Text on Packages & Labels

- Read and Verify 2D Codes on a Product or Container

- Color Sorting and Inspection

- Detect Presence of Instruction Leaflets & Damaged Capsules in Blister Packs

Compliance, traceability, authentication

- Improve customer safety

- Prevent counterfeiting

- Stop parallel trade and sale through unauthorized channels

- Minimize losses

- Provide recall efficiency

Process control and supply chain management

- Improve management of work in process

- Reduce inventory

- Optimize availability and use of production tools

- Minimize distribution of non-conforming products

Automate production

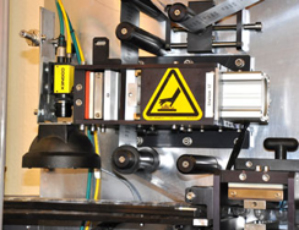

You may also consider using machine vision in tandem with robotics when picking loose products off of a conveyor to feed a process or palletizing cases for distribution. Vision-guided robotics also eliminates the need to physically handle the products.

- Eliminate costly precision part fixtures

- Improve product safety by minimizing the risk of contamination due to human contact

- Provide production flexibility without tooling changeover

Read More About Cognex for the Pharmaceutical & Medical Industry

Robotics: Helping the Workforce with Dirty, Dangerous, Dull, or Repetitive Jobs

New Levels of Productivity Reached with Robots

Industrial robots give your assembly line flexibility and safety, reduce production time, and raise production yields. From robots with high speed and precision, to those that are collaborative, lightweight, and easily re-deployed, there are many beneficial options.

Collaboratives:

- Can Safely Work Beside Humans

- Easily Programmed

- Perform Dangerous, Dull, or Dirty Tasks

High-Speed:

- High Precision

- Reliable and Quick Packaging

- Sort Products or Orient them for Filling or Packaging

- Perform Dangerous, Dull, or Dirty Tasks

Copyright @2020 -2023 · All Rights Reserved ·

Advanced Control Solutions

1400 Williams Dr, Marietta, GA 30066