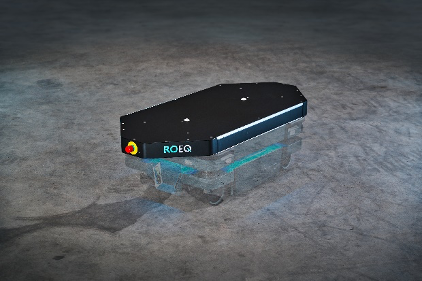

ROEQ designs, develops and manufactures standard robotic equipment that helps you get the most out of your MiR autonomous mobile robots (AMR). Whether you need to pick up /drop off carts, racks, pallets etc or transfer loads to conveyor stations, the ROEQ range with ROEQ Assist software provide safe, reliable solutions.

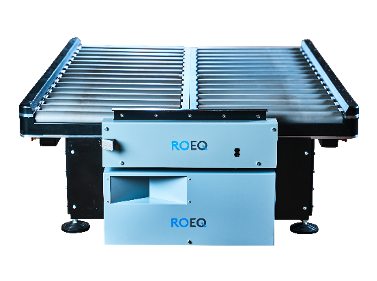

The ROEQ TR125 Manual enables automated transportation of crates and flat-bottomed goods between conveyor stations.

The ROEQ TR125 Auto is an auto-adjustable top roller for the MiR100, MiR200 and MiR250. It enables you to schedule pick-up and delivery tasks between stationary conveyor stations at different heights with no manual intervention.

TR125 Auto Datasheet

The ROEQ TR600 is a heavy duty top roller for MiR600 AMRs (Autonomous Mobile Robots). They can pick up and deliver heavy goods between conveyor stations and are ideal for transporting US, euro pallets and various cargo types.

The full solution includes the ROEQ GuardCom system which provides additional safety and efficiency when transferring between the top roller and the receiving station, using robust sensor technology.

The ROEQ TR1000 Auto enables your MiR600 or MiR1350 AMR to transfer heavy goods between conveyor stations at different heights. The automatic height adjustments, with a large stroke – 240 mm/9.4” –gives the flexibility to adjust to your existing setup.

Note the two package function, which allows you to pick up or drop off packages separately to two stations.

The ROEQ TR1150 is a heavy duty top roller for MiR1150 AMRs (Autonomous Mobile Robots). They can pick up and deliver heavy goods between conveyor stations and are ideal for transporting US, euro pallets and various cargo types.

The full solution includes the ROEQ GuardCom system which provides additional safety and efficiency when transferring between the top roller and the receiving station, using robust sensor technology.

The ROEQ GuardCom System, is a wireless solution that enables all ROEQ top rollers to work seamlessly with any stationary conveyor stations. It has a small footprint, so it takes up minimal space. Features robust sensor technology doesn’t rely on unstable Wi-Fi connections.

Guardcom Datasheet

The ROEQ Top Module Lifter TML200 for the MiR250 is a flexible top module that can function as a lifter for pallets, crates and racks, as well as for shelf carts. As a lifter, crates or pallets can be picked up, transported and dropped off using the ROEQ PR250 pallet rack as a pick-up/drop off station. Depending on requirements, the pallet rack can be set against a wall or used as a free-standing rack that enables the mobile robot to deliver the load and continue driving through. The pallet rack can also be set up in multiples, side by side, for a scalable solution.

TML200 Datasheet

The ROEQ TML1200 is a heavy-duty industrial lifter solution for internal transport of goods using your MiR500, MiR600, MiR1000 and MiR1350 robots. Goods can be picked up and delivered at different heights, due to its large stroke. This lifter doesn’t have to return to the lowest position during transport, which reduces cycle time. Equipment can be mounted on top using the attachment holes.

TML1200 Datasheet

Use with ROEQ S-Cart300 series on the MiR250 for payloads up to 300 kg. This extended top module enables the handling of longer goods like larger EU and US pallets with an emergency stop that’s accessible even with larger goods on board.

TMS-C300 Ext Datasheet

Use with ROEQ S-Cart500 series on the MiR250 for payloads up to 500 kg. The extended top module enables the handling of longer goods like larger EU and US pallets with an emergency stop that’s accessible even with larger goods on board.

TMS-C500 Ext Datasheet

The ROEQ TMS-C1500 with the S-Cart1500W transports up to 800kg with the MiR500 and MiR600 and up to 1500kg with the MiR1000 and MiR1350. Can handle different types and sizes of goods on multiple missions, giving you maximum use of your robot.

TMS-C1500 Datasheet

The TMC300 is a cart module that is used with docking stations. It is compatible with MiR100, MiR200 and MiR250 + AM250 robots. It features our patented locking mechanism, which safely secures the cart under transport and ensures that the robot always knows the location of the cart. It works with both Precision docking and our Easy-Pull-Out docking that allows the carts to be handled by human workers. There are mounting holes on top of the carts for mounting customized equipment.

The TMC300 Ext is a cart solution with an extended footprint for transporting longer goods like pallets in a setup using docking stations. It’s made for the MiR100, MiR200, MiR250 + AM250 robots. The extended footprint features an emergency stop button that’s accessible even when transporting larger goods.

TMC300 Ext Datasheet

The TMR150 is a flexible top module that’s designed to be used with racks/carts or as a lifter solution on your MiR100, MiR200 and Mir250 + AM250 robots. It can work with cart and lifter solutions in the same setup and must be used with docking stations. The carts/racks have mounting holes to add equipment or customized to your needs.

TMR150 Datasheet

Cart for the MiR250 and the MiR Shelf Carrier 250 that enables your robot to pick up and drop off in free space.

A shelf cart developed to pick up, transport and drop off loads of up to 500 kg/1100 lbs, in free space, when combined with the ROEQ TMS-C500 Ext top module and the MiR250.

A shelf cart developed to pick up, transport and drop off loads of up to 500 kg/1100 lbs, in free space, when combined with the ROEQ TMS-C500 Ext top module and the MiR250. The increased wheelbase gives increased tilt stability for longer goods.

Cart for the MiR250 has a 6-wheel design which makes it easy for personnel to manually maneuver in straight lines – such as through long, narrow corridors.

Cart for the MiR250 with increased wheelbase, which gives increased tilt stability for longer goods that extend beyond the 790mm footprint of the standard S-Carts . The 6-wheel design means it can be easily maneuvered manually in straight lines by personnel over longer distances – such as through long, narrow corridors. Use with the MiR250 and the ROEQ TMS-C300 Ext top module to move larger goods like pallets and cages between logistic key points.

The S-Cart300L cart for the MiR250 has been developed to work with the TML200 top module. This cart enables the TML200 to lift and transport payloads up to 170kg/374lbs. on the MiR250, allowing it to maneuver in situations where floors have reduced traction e.g. on polished or dusty floors.

Advanced Control Solutions is a ROEQ distributor in Georgia, Tennessee, Alabama and Mississippi. We offer free evaluations and technical support to help our customers solve their applications.

Copyright @2020 -2023 · All Rights Reserved ·

Advanced Control Solutions

1400 Williams Dr, Marietta, GA 30066