Robotiq designs and manufactures flexible robot grippers and complimentary components. Robotiq works with robot manufacturers, integrators and end-users to deliver dexterous grippers that enable new applications and improve productivity.

The 2-Finger Adaptive Robot Gripper has been designed to match Universal Robots in terms of payload, flexibility and user-friendliness.

The 2-Finger Gripper has also been designed to make its installation and programming with Universal Robots easily accessible for everyone. The embedded URCap software also allows the use of several Grippers on the same UR arm.

For maximum versatility and flexibility, the 3-Finger Gripper is the best option. Ideal for advanced manufacturing and advanced robotic research, the 3-Finger Gripper will pick up any object of any shape. The 3-Finger Adaptive Robot Gripper has been designed to match Universal Robots in terms of payload, flexibility and user-friendliness. This robot hand has also been designed to make its installation and programming with Universal Robots easily accessible for everyone.

Robotiq's Camera brings Plug + Play vision for Universal Robots.

Robotiq’s Force Torque Sensors give your Universal Robot the sense of touch. Because it’s a digital signal, the Force Torque Sensor is not affected by surrounding noise and provides a stable, precise measurement of force applied on the process or part.

By installing a Force Torque Sensor on your robot, you’ll be able to reliably perform the following tasks:

Force Copilot is an intuitive software to operate Universal Robots e-Series’ embedded force torque sensor. It accelerates the programming of a whole host of applications, including part insertion and surface finding. Its sensing functions increase flexibility and reliability in machine-tending, assembly, finishing, and pick-and-place applications.

Robotiq Vacuum Grippers can handle a wide range of applications and are ideal for picking up uneven and even workpieces made of different materials, such as cardboard, glass, sheet metal (dry) and plastic. Because of the customizable bracket and unique air nodes, Robotiq Vacuum Grippers provide manufacturers full control over their Gripper to make sure it’s a perfect fit for their applications. The EPick uses electricity, is connected to the robot wrist, and is easy to handle. The AirPick uses compressed air for a powerful vacuum flow, has low noise, and is a compact design for cobots.

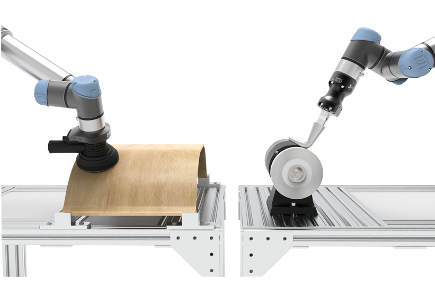

Sanding applications for collaborative robots require many hardware and software components to communicate together. Integration can take months- but not anymore, with Robotiq’s sanding kit.

Supported materials include wood, plastic, metal, fiberglass, solid surface, and carbon fiber.

![]() Robotic Machine Tending: How to Improve CNC Machine Production

Robotic Machine Tending: How to Improve CNC Machine Production

![]() CNC Machine Tending Application eLearning

CNC Machine Tending Application eLearning

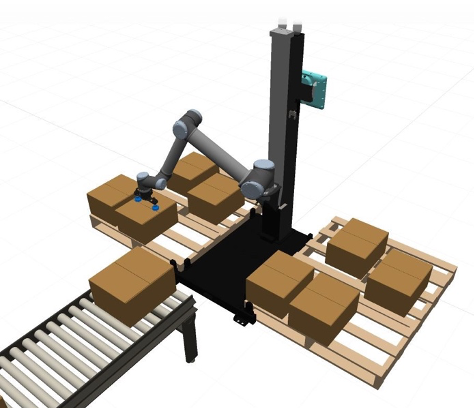

With the Robotiq Palletizing Solution, simplicity meets flexibility. Set up your application in 3 easy steps. Experience how seamless it is to use the Robotiq application software called Material Handling Copilot. Enjoy a quick and 3 easy-step setup through its user-friendly platform. Generate and automatically optimize all trajectories and robot movements using only the below information:

![]() Download our Palletizing Solution Guide

Download our Palletizing Solution Guide

Designed for manufacturers looking to automate screwdriving applications, this new solution's intuitive features eliminate the need for expensive, complicated custom-designed solutions. The Robotiq Screwdriving Solution gets the work done right. In simple small-screw assemblies, it enables 5-minute changeovers, so manufacturers can produce multiple products per assembly line. Plus, it's affordable and easy to deploy.

Robotiq Screwdriving URCap simplifies programming, because it automates the force- sensing capabilities, as well as the communication between the screwdriver, screw feeder, robot, and vacuum technology.

![]() Read more About Screwdriving Solution

Read more About Screwdriving Solution

Robotiq just released a three-step, systematic way to complete the robotic cell deployment cycle, from design to integration and operation. It will empower your team to deploy robots quicker and more efficiently than ever before. Lean Robotics covers the complete robot cell deployment. It helps you get to production faster, increase productivity and achieve ROI quickly.

Check out the new Lean Robotics book, written by the CEO of Robotiq, Samuel Bouchard. Whether you’re a manufacturing manager or engineer, if you’re ready to make robots work for you, this book will show you how.

Free Lean Robotics eBook Download

Copyright @2020 -2023 · All Rights Reserved ·

Advanced Control Solutions

1400 Williams Dr, Marietta, GA 30066