MiR

MiRMobile Industrial Robots is a leading manufacturer of collaborative mobile robots. They are dedicated to developing user-friendly, flexible and safe robots to help companies increase the efficiency of their operations. These autonomous robots are a new generation of advanced mobile robots which give you a rapid return on investment, often with a payback period of less than a year.

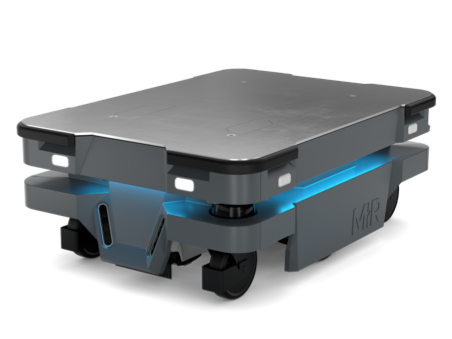

The MiR250 is a more flexible AMR that can work around the clock and is brilliantly simple to setup, for improved productivity. Its smaller footprint and increased adaptability help optimize internal logistics without changing layout. The MiR250 is packed with the newest technology, designed for serviceability and it can navigate smoothly and efficiently in dynamic environments – and even drive through doors as narrow as 80 cm!

Ideal for a wide range of towing jobs:

MiR Hook 250 TM is ideal for a wide range of towing jobs, such as efficiently moving heavy products between locations in a manufacturing facility or warehouse. The MiR250 Hook supports the transport of loads up to 500 kg (1100 lbs), providing exciting new internal logistics options for weighty or unwieldy cargos.

Improved software and robot base:

The MiR250 Hook is applying the newest software for optimal output. The MiR250 Hook combination is more agile due to its improved software and the stronger robot base, making the MiR250 Hook an improved AMR solution in terms of performance, precision and productivity.

The MiR600 is a stronger and safer AMR. It also is compliant with the highest available robot standards- The MiR600 is the first IP52 rated AMR on the market, together with MiR’s other heavy-duty robot, the very powerful MiR1350. With increased ability to withstand dust particles and fluids the mobile robot can be used in more environments, it can e.g. drive close to open gates or other places where it is exposed to waterdrops and dirt.

MiR600 is equipped with the latest laser-scanning technology that delivers a 360-degree visual for optimal safety. 3D cameras have a range of 30-2,000 mm above floor level to detect pallets.

With a payload of 1350 kg (3000 lbs), MiR1350 is the most powerful AMR from MiR to date, and it enables you to maximize the efficiency of your logistics operations. MiR1350 has, with specially designed pallet lifters from MiR, the ability to pick-up, transport and deliver pallets automatically. Thereby, the collaborative robot is a safe alternative to traditional pallet lifters and trucks, which many companies wish to get away from the factory floor, since they often compose a safety risk.

The MiR1350 is the first IP52 rated AMR on the market. This means that it has enhanced and protected components, so it can withstand dust particles and fluids. The MiR1350 can be used in more environments as it can drive close to open gates or other places where it is exposed to waterdrops and dirt. The MiR1350 is designed to comply with the highest available safety standards - ISO3691-4, making it superior to other AMRs on the market.

With MiR Shelf Lift, the MiR500 and MiR1000 can autonomously connect to a cart, transport and deliver it wherever you need. It ensures a flexible transportation of your heavy loads of different sizes and your pallets, without the need of a pallet rack. One robot can now pick up or deliver multiple carts, wherever you need it.

Looking to optimize safety and efficiency of your pallet handling? A MiR600 or MiR1350 equipped with the MiR Pallet Lift 600 or 1350 top module is your solution! The MiR Pallet Lift top module securely handles different sizes on pallet, e.g. 40" x 48" pallets, and other loads, enabling MiR to autonomously lift and transport payloads up to 500 kg.

This solution will help you optimize pallet transport without the need for facility changes. MiR with Pallet Lift autonomously moves pallets at 2 m/sec ensuring a fast throughput, and frees up staff for higher valuable tasks.

The MC600 is powerful new mobile cobot integrating Mobile Industrial Robots’ MiR600 with Universal Robots’ heavy-payload UR20/UR30 cobot.

This solution automates complex workflows in industrial environments, excelling at handling heavier items and automating tasks. The UR20’s extended reach allows the MC600 to tackle tasks in areas previously inaccessible to smaller cobots, enhancing productivity across diverse industrial applications such as palletizing, box handling, and machine tending.

The MiR1200 Pallet Jack revolutionizes internal pallet transportation, automating detection, transport, and delivery of EU pallets up to 1200 kg at 1.5 m/s. Its groundbreaking AI-based perception system sets it apart, reducing pick-and-place cycle times significantly and elevating throughput.

This agile robot operates continuously, with shift-long battery capacity and seamless opportunity charging for uninterrupted performance. Navigating tight spaces effortlessly, it optimizes logistics efficiency, ensuring timely pallet delivery without additional infrastructure.

Read more about MiR1200 Pallet Jack

The MiR Shelf Carrier 250 top module is a standard module, which fits to the MiR250, enabling the robot to collect and deliver shelves, carts and other applications.

With the MiR250 Shelf Carrier solution, you can efficiently transport and deliver multiple carts and shelves across your facility. This approach optimizes the utilization of your MiR250 robots, surpassing the limitations of fixed shelves directly mounted on the robot.

Read more about the Shelf Carrier 250

MiRFleet™ gives you centralized control of robots throughout your facility from a single, user-friendly, web-based interface.

Easy programming of robots for multiple jobs

You can easily program and control a fleet of robots, including managing robots with different top modules, hooks or other accessories. Once programmed, the system automatically prioritizes and selects the robot best-suited for a job based on position and availability. SMS or email notifications keep you informed of obstacles or other issues that might prevent the robot from completing a task.

Addresses the complex needs of enterprise-level customers seeking end-to-end solutions. A scalable, flexible and secure fleet management software platform designed to optimize overall material handling workflows to boost productivity.

Your MiR robot will never run out of power in the middle of a job. MiRCharge™ is a fully automatic charging station that offers flexible deployment options to meet your needs.

Collaborates with MiRFleet™

The robot autonomously returns to the charging station and connects when its battery falls under established limits. It can also be programmed to regularly recharge between deliveries, such as when it returns to a stockroom or depot, which can allow the robot to run nearly continuously. MiRCharge™ fully charges a MiR robot in about two hours. When multiple robots are deployed using MiRFleet™, the system evaluates battery levels and job loads, optimizing utilization and recharging to keep the fleet on the job around the clock.

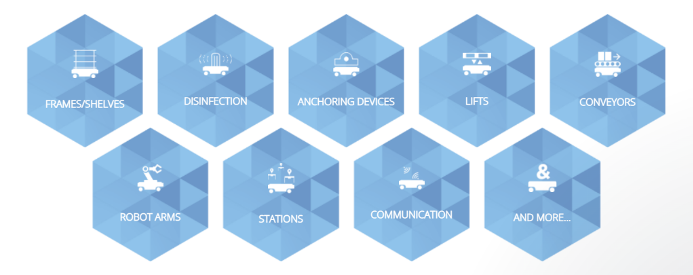

MiRGo is the largest ecosystem for AMRs- it's an open robot platform ready for different applications to be integrated. In new MiRGo, you can find applications from third party suppliers that extend the functionality of MiR robots.

MiRGo consists of many different applications and top modules for all the different options in MiR's product portfolio, and you can easily customize your robot with off the shelf solutions. In this marketplace, you can get inspiration for how our mobile robots can create value for you, your colleagues and your production.

Advanced Control Solutions is a MiR Robot distributor in Georgia, Tennessee, Alabama and Mississippi. We offer free evaluations and technical support to help our customers solve their applications.

Copyright @2020 -2023 · All Rights Reserved ·

Advanced Control Solutions

1400 Williams Dr, Marietta, GA 30066