Applied Motion Products specializes in high-precision, cost-effective motion control products. They offer a full complement of stepper and servo, drives, motors, controllers, gearheads, and power supplies to serve a diverse industrial and OEM customer base.

StepSERVO™ is the next evolution in step motor technology. Starting with a proven integrated motor design, we add a high-resolution 5000 line incremental encoder (20,000 counts/rev) and closed-loop servo firmware to create a motor that offers the best step motor performance available today.

StepSERVO Motors are specifically designed to be paired with our StepSERVO Drives to create motor and drive combinations that outperform traditional step motor systems. Each StepSERVO Motor is a premium, two-phase, hybrid step motor built with an integral high resolution feedback device. The performance gains achieved when using a StepSERVO Motor in combination with one of our StepSERVO drives include high peak torque ranges for faster acceleration and greater machine throughput, as well as quieter operation and less power consumption.

StepSERVO Drives are the closed-loop versions of our well-established, high-performance, microstepping step motor drives. By incorporating closed-loop servo control algorithms in these drives and pairing them with StepSERVO Motors with high-resolution encoders, we are able to create StepSERVO systems with performance that greatly exceeds conventional step motor performance. Peak torques as much as 50% higher, smoother, quieter operation and lower power consumption are just some of the benefits of StepSERVO Drive and Motor systems.

The SV200 servo drives utilize programmable notch filters, an anti-vibration algorithm and auto-tuning. These features ensure smooth motion and accurate positioning for the most demanding applications, as well as an easy means of configuring the drive. The SV200 servo drives are designed to be used with J Series servo motors in the 200W, 400W and 750W power range. Select the control option of the SV200 servo drive that best meets your control requirements. For basic pulse & direction or analog torque/velocity applications choose the P model. For streaming commands, stored program execution or Modbus communications choose the Q model. For CANopen networking choose the C model, and for EtherNet/IP networking choose the IP model.

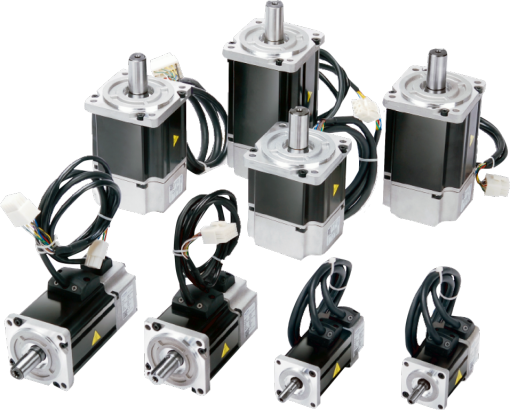

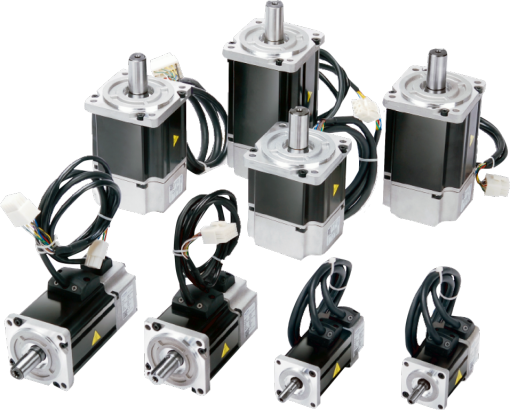

J Series High-torque brushless servo motors in NEMA and metric frame sizes. J series motors come in a 40, 60, or 80 mm frame size, along with a 10,000 count incremental commutating encoder. 100 to 750 watts, IP65, UL and CE rated with optional holding brake. Also featured are value priced Servo Sets, pairing the J series with digital servo drives and cables to provide a complete system right out of the box.

Drives and Integrated Motors with EtherNet/IP Communication Ports. With EtherNet/IP users can control, configure and query drives using an open, standards-based, industrial Ethernet connection at speeds up to 100 MBits/sec.

Applied Motion drives and motors with EtherNet/IP – designated by “IP” in the model number – run all of the same control modes as “Q” drives, with the addition that all drive features can be accessed over EtherNet/I. EtherNet/IP is an industrial Ethernet network solution built on the Common Industrial Protocol (CIP), and is supported by the ODVA.

Applied Motion Products has specialized in offering two-phase, hybrid step motors in a variety of frame sizes. These motors are designed to work optimally with Applied Motion stepper drives, ensuring smooth motion and high performance in every application. Add an encoder to the rear shaft of an Applied Motion step motor, marry it to an Applied Motion drive equipped with encoder-feedback functionality, and dramatically improve system performance.

STM integrated drive+motors fuse step motor and drive components into a single device. These integrated steppers offer a space-saving design that reduces wiring and saves on cost over separate motor and drive components. STM integrated steppers, in NEMA 17, 23, and 24 frame sizes, combine the best of Applied Motion’s drive and motor offering in a single, integrated device.

The STR3 drive features advanced microstepping performance and sophisticated current control with anti-resonance. Each STR3 drive can microstep up to 20,000 steps/rev with a 1.8° step motor (1/100 step), and can even microstep the step motor when the command pulses are low resolution. This feature is called Microstep Emulation. Anti-resonance electronically damps motor and system resonances, which improves motor smoothness and torque over a wide speed range.

Advanced Control Solutions is a Applied Motion Products distributor in Georgia, Tennessee, Alabama and Mississippi. We offer free evaluations and technical support to help our customers solve their applications.

Copyright @2020 -2023 · All Rights Reserved ·

Advanced Control Solutions

1400 Williams Dr, Marietta, GA 30066